Choosing the Right Reflective Vinyl

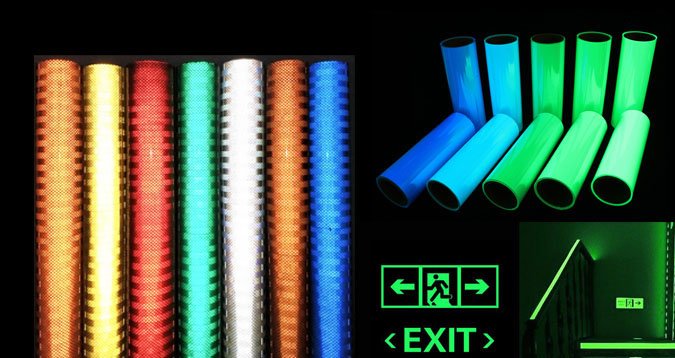

Types of Reflective Vinyl

1. Standard Reflective Vinyl

– This type is suitable for most applications and is commonly used for safety gear, signage, and apparel.

2. Engineer Grade Reflective Vinyl

– Known for its durability and high visibility, engineer grade vinyl is often used for road signs and commercial applications.

3. High-Intensity Reflective Vinyl

– Offering superior brightness and visibility, high-intensity vinyl is ideal for high-risk areas and emergency signage.

4. Oralite Reflective Vinyl

– Recognized for its exceptional brightness and long-distance visibility, Oralite is a premium brand often used in professional applications.

Considerations for Selection

1. Intended Use

– Determine the purpose of your project. Is it for safety gear, signage, fashion, or something else?

2. Durability

– Consider factors like outdoor exposure, frequent handling, and washability.

3. Visibility Requirements

– Evaluate the level of visibility needed for your project. For high-traffic or critical safety applications, a higher-grade reflective vinyl might be necessary.

4. Budget

– Reflective vinyl comes in various price ranges. While premium brands may offer superior performance, standard options may be suitable for less demanding applications.

5. Compatibility with Fabric or Surface

– Ensure the chosen vinyl is compatible with the material you intend to apply it to. Some vinyl types may adhere better to certain fabrics or surfaces.

6. Brand Reputation

– Established brands often have a track record of quality and performance.

Tools and Supplies Needed

Here’s a breakdown of essential tools and optional equipment for working with reflective iron-on vinyl:

Essential Tools:

1. Cutting Machine:

– A quality cutting machine like a Cricut or Silhouette that can handle vinyl materials.

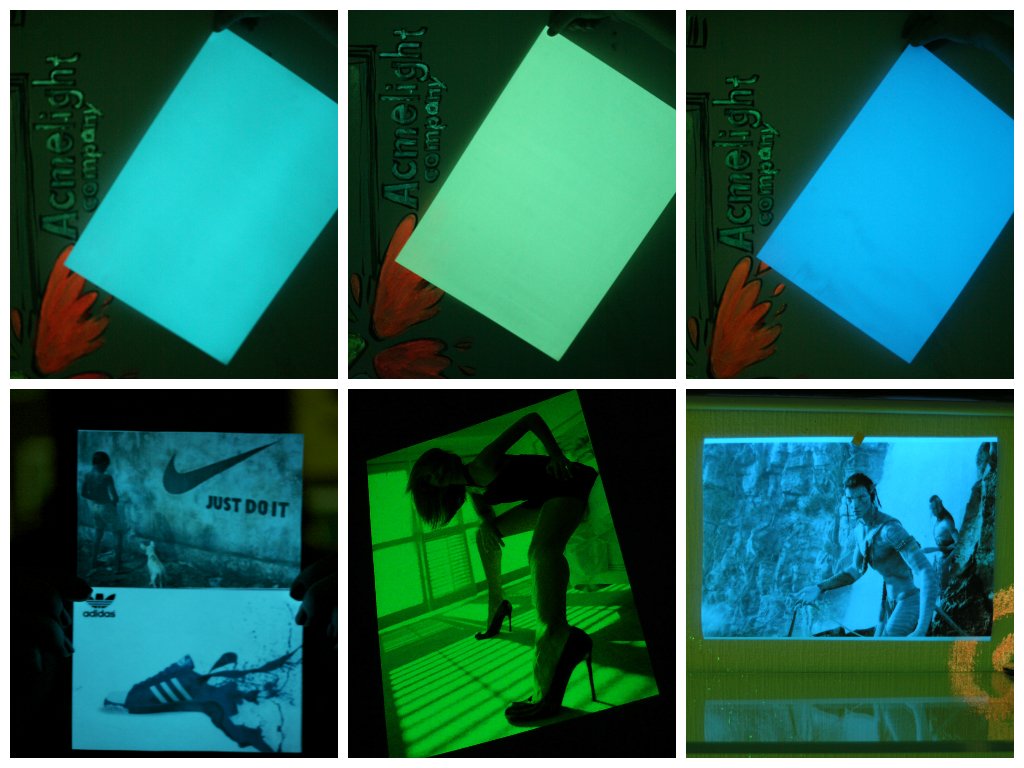

2. Reflective Iron-On Vinyl:

– Choose a high-quality reflective iron-on vinyl in the colors and finishes you desire for your project.

3. Weeding Tools:

– Weeding hook or tweezers for removing excess vinyl from the design.

4. Heat Press or Iron:

– A heat source to apply heat and pressure for adhering the vinyl to the fabric.

5. Protective Cover Sheet:

– Parchment paper or a Teflon sheet to protect the vinyl and fabric during the heat application process.

6. Teflon Sheet or Heat Transfer Pillow (Optional):

– These can help provide even pressure during the heat application process, especially for items with uneven surfaces.

Optional Tools for Precision and Ease of Use:

1. Vinyl Scraper or Brayer:

– Helps to smooth out the vinyl and ensure it adheres properly to the fabric.

2. Cutting Mat:

– Provides a stable surface for cutting the vinyl and helps protect your work area.

3. Precision Knife or Detail Scissors:

– Useful for making intricate cuts or adjustments to the vinyl design.

4. Heat-Resistant Tape:

– Helps to hold the design in place during the heat pressing process.

5. Multi-Use Paper (Non-Stick):

– Can be used as a cover sheet during the heat application process.

6. Measuring Tools:

– Ruler or measuring tape for accurate placement and sizing of the design.

7. Lint Roller:

– Ensures that the fabric is clean and free of any debris before applying the vinyl.

8. Spray Bottle with Water and a Drop of Dish Soap:

– Helps with positioning and adjusting the vinyl before it’s fully adhered.

9. Design Software (if not using pre-made designs):

– Software like Adobe Illustrator, Inkscape, or design programs specific to your cutting machine for creating custom designs.

Having these tools on hand will help you work with reflective iron-on vinyl more effectively and achieve professional-looking results. Remember to follow safety precautions when using heat-related tools, and always refer to the manufacturer’s instructions for your specific equipment.