SINOVINYL, a renowned name in the world of Reflective Sheeting, takes pride in its commitment to quality and innovation. Have you ever wondered what goes on behind the scenes in the creation of their exceptional reflective products? Join us on a journey through the intricate process that transforms raw materials into the high-impact reflective solutions that adorn our world.

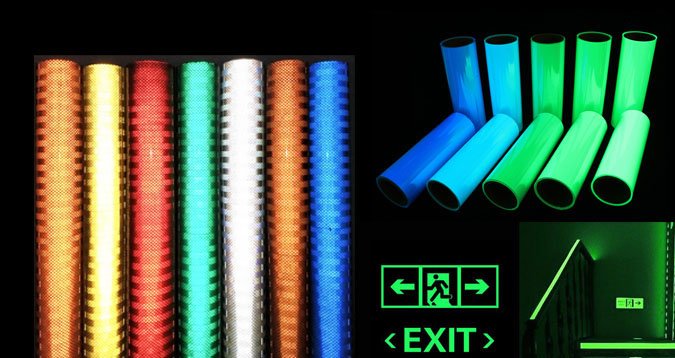

Raw Materials: The Foundation of Brilliance

The journey begins with the selection of high-quality raw materials.

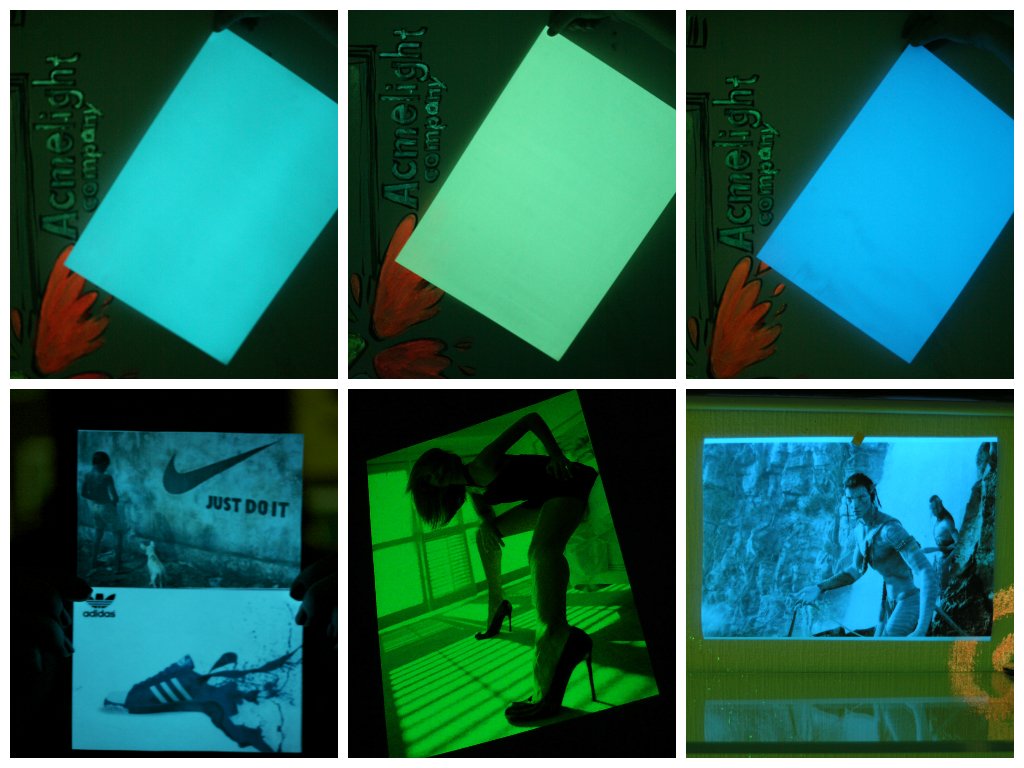

Reflective Coating: SINOVINYL uses a specialized reflective coating that ensures optimal light reflection and longevity.

Backing Material: The reflective coating is applied to a durable backing material, providing the sheeting with its structural integrity.

Coating Application: Precision Matters

The reflective coating application is a critical step in the manufacturing process.

Consistency is Key: Advanced machines are used to apply the reflective coating evenly, ensuring uniform brightness across the sheet.

Precision Timing: The speed and timing of the coating application are meticulously controlled to achieve the desired reflectivity.

Curing and Drying: The Art of Setting Brilliance

Once coated, the sheeting goes through a curing and drying process.

Heat and Time: Controlled heat and time settings are employed to cure the reflective coating, making it durable and resilient.

Complete Drying: Ensuring that the sheeting is entirely dry is crucial to maintain its reflective properties.

Cutting and Shaping: Precision Craftsmanship

After curing and drying, the sheeting is cut and shaped according to specific requirements.

Customization: SINOVINYL offers a range of shapes and sizes to cater to diverse applications.

Laser Precision: Advanced cutting machinery ensures accurate dimensions, which are vital for the sheeting’s performance.

Quality Control: Stringent Measures

Quality is the cornerstone of SINOVINYL’s manufacturing process.

Rigorous Testing: Each batch undergoes extensive quality checks to ensure it meets global standards.

Real-World Simulations: Some tests simulate real-world conditions, such as exposure to varying temperatures and UV radiation.

Backing Material Application: Adding Structure

The reflective sheeting is then paired with a backing material.

Adhesive Layer: The backing material often includes an adhesive layer, facilitating easy installation.

Lamination: The sheeting and backing material are laminated together with precision, creating a composite product.

Packaging and Shipping: Ready for the World

The final step is packaging and shipping.

Protective Measures: The sheeting is carefully packaged to prevent damage during transit, ensuring it reaches customers in perfect condition.

Global Distribution: SINOVINYL’s products are shipped worldwide, making quality reflective solutions accessible to a diverse range of clients.

Conclusion

Behind every brilliant Reflective Sheeting product from SINOVINYL lies a meticulous and sophisticated manufacturing process. From selecting the finest raw materials to rigorous quality control measures, every step is a testament to the brand’s commitment to excellence. As these high-impact reflective solutions light up our world, they reflect the essence of SINOVINYL: precision, quality, and innovation.