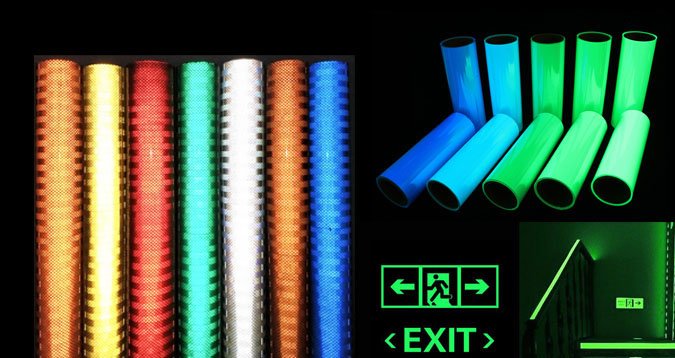

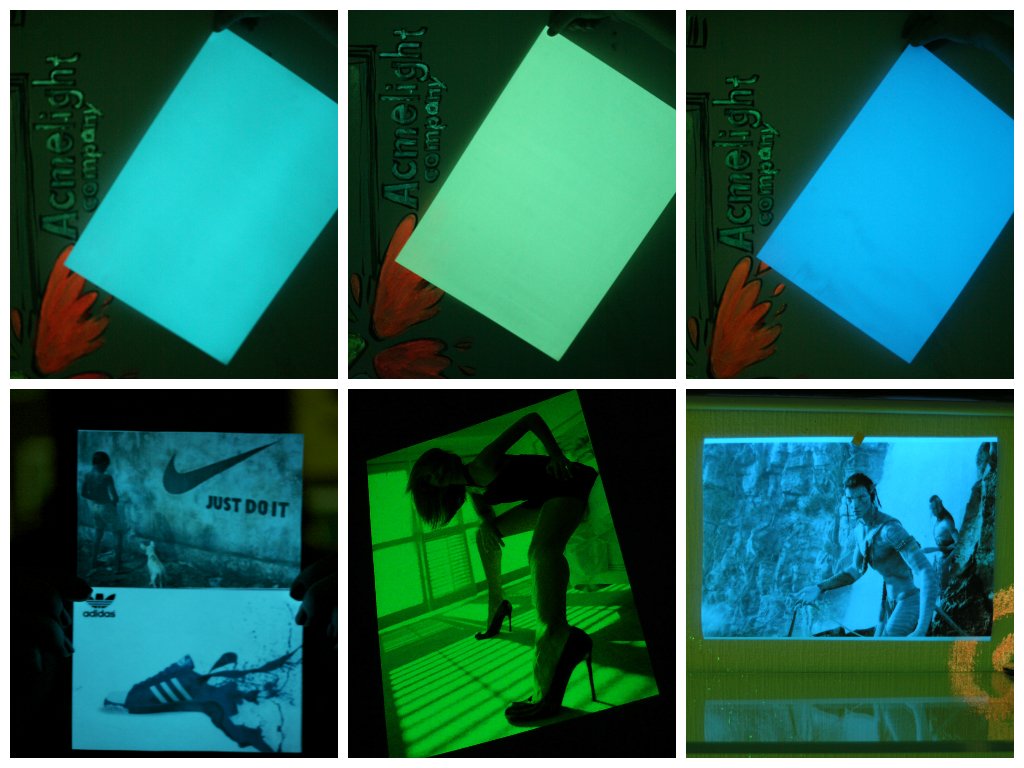

The allure of reflective sheeting in designs, whether on vehicles, signboards, or artistic installations, is undeniable. However, the application process can often deter individuals due to the fear of imperfections, like bubbles or wrinkles. SINOVINYL, a leading brand in the domain, recognizes this challenge and offers invaluable insights. Here’s a comprehensive guide with expert tips on achieving a flawless reflective sheeting application.

Preparation: The Foundation of Perfection

Before diving into the application process, ensuring the surface is ready is crucial.

- Clean the Surface: Any dust or dirt can impede the vinyl’s ability to adhere properly. Clean the surface thoroughly using a mix of water and a few drops of dish soap. Make sure it’s completely dry before application.

- Select Quality Materials: Not all reflective sheetings are made equal. Opt for trusted brands like SINOVINYL to ensure the product itself is of the highest quality.

Tools of the Trade: Equipping Yourself

The right tools can make all the difference.

- Squeegees and Felt Edges: These tools help smooth out the vinyl and push out any air bubbles. Using a felt edge can prevent scratching the vinyl.

- Air Release Tool: Small bubbles may still form despite your best efforts. An air release tool, or even a fine needle, can be used to poke a tiny hole and release trapped air.

- Heat Gun: This is especially useful for applying reflective vinyl on curved surfaces. Heating the vinyl makes it more pliable and easier to stretch without wrinkling.

Application: The Step-by-Step Guide

Now, to the most vital part.

- Peel and Stick Method: Start at one edge and slowly peel the backing while pressing the vinyl onto the surface. Use a squeegee to smooth it out as you go.

- The Hinge Method: For larger pieces, tape the vinyl in place using painter’s tape, then peel back half the backing and cut it off. Apply that half using a squeegee, then remove the other half of the backing and continue the application.

- Smooth Out Bubbles: Using your squeegee, push bubbles towards the edge to release the trapped air. For stubborn bubbles, use the air release tool.

- Setting the Vinyl: Once applied, it’s advisable to go over the vinyl with a heat gun (from a safe distance) to ensure it sets correctly on the surface.

Aftercare: Ensuring Longevity

Your reflective sheeting is now flawlessly applied, but how do you ensure it remains that way?

- Clean with Care: When cleaning the applied area, avoid abrasive tools. A soft cloth or sponge works best.

- Avoid Harsh Chemicals: Cleaning agents with harsh chemicals can deteriorate the adhesive over time. Stick to milder cleaning agents.

- Check for Wear and Tear: Periodically check the vinyl for any signs of wear or lifting edges. Addressing issues early can prevent further damage.

Conclusion

Applying reflective sheeting without imperfections may seem daunting, but with the right guidance, tools, and quality products like SINOVINYL’s range, it’s an achievable feat. A flawless application not only looks professional but also extends the lifespan of the vinyl. With these expert tips at your disposal, your next reflective sheeting application project will shine bright without a wrinkle in sight!