Understanding the Science Behind Heat Transfer Reflective Vinyl

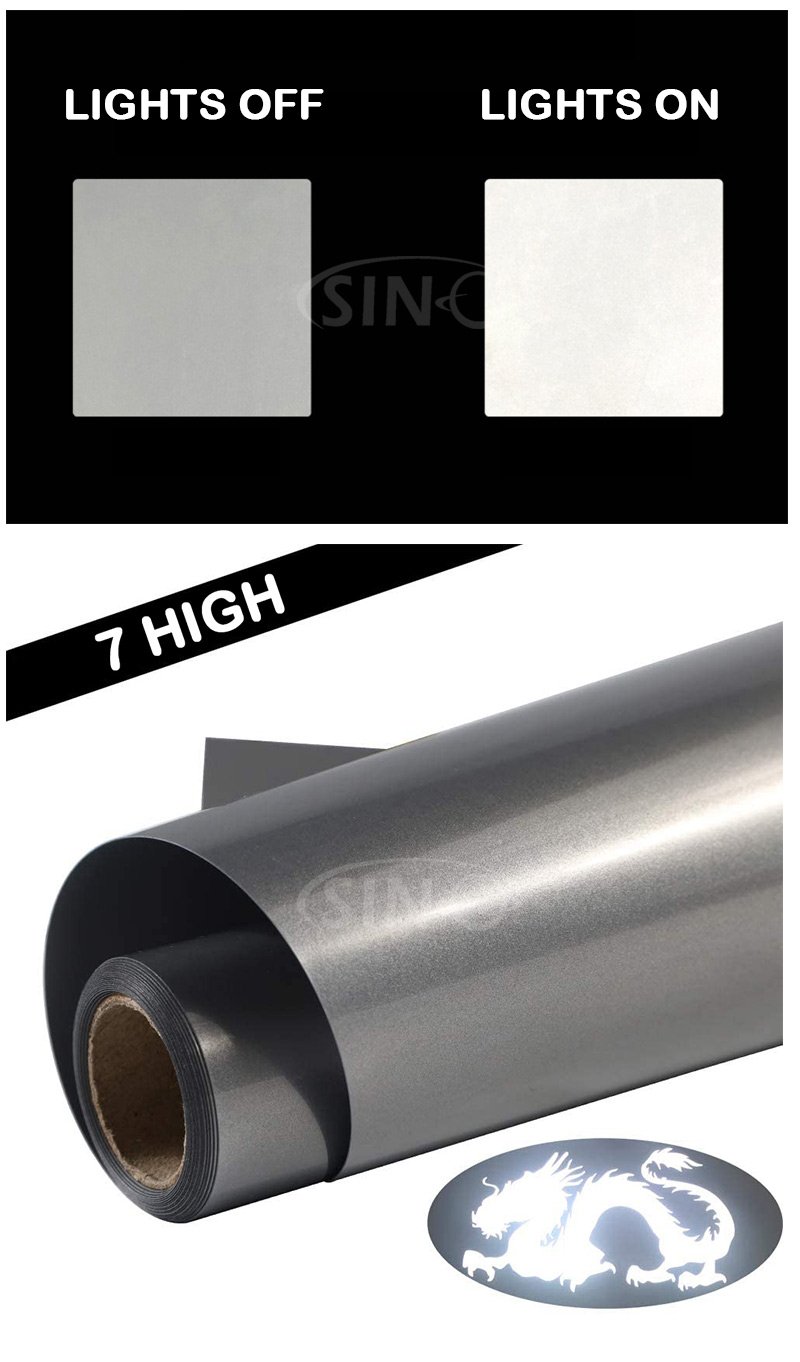

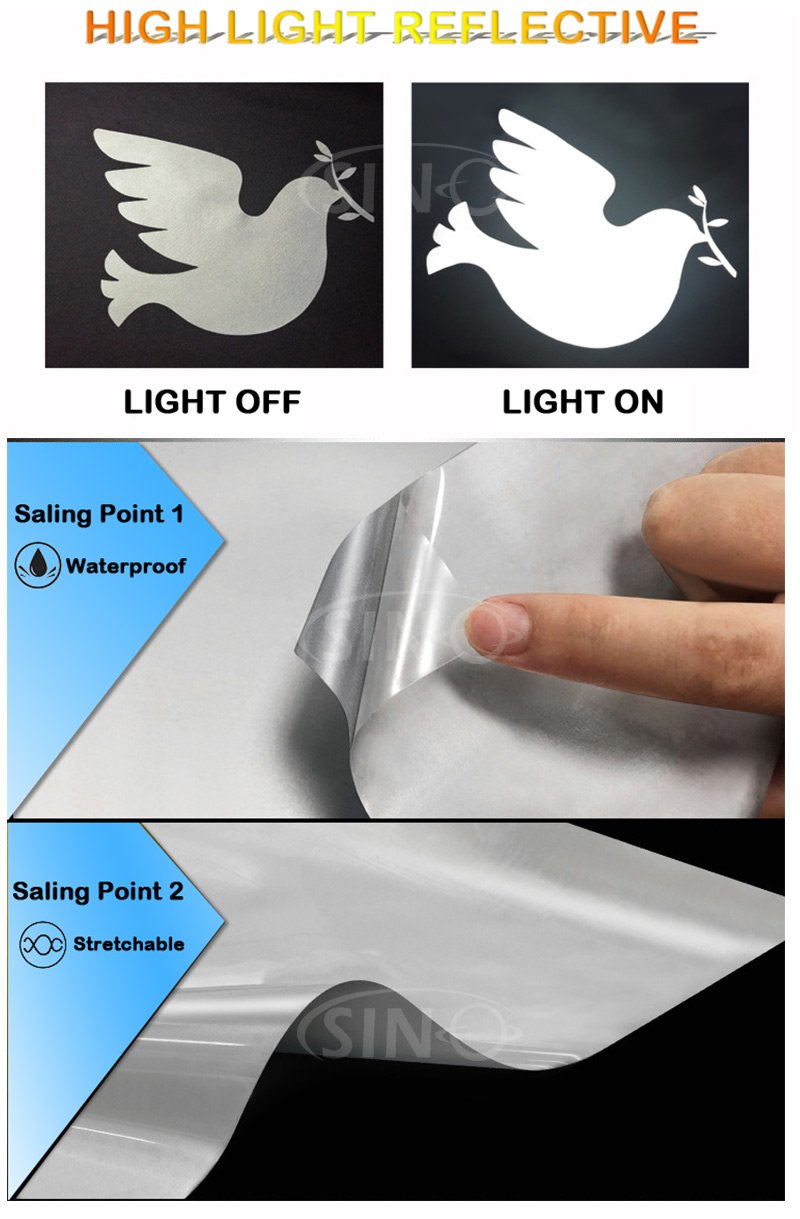

Heat transfer reflective vinyl is designed to enhance visibility and safety by reflecting light back to its source. The science behind its functionality lies in its unique composition and reflective properties.

1. Retroreflection: Heat transfer reflective vinyl utilizes a concept known as retroreflection. It consists of tiny glass beads or microprisms embedded on the surface of the vinyl. When light strikes the vinyl, these beads or prisms bounce the light back in the direction it came from, rather than scattering it in different directions.

2. Refraction and Total Internal Reflection: The glass beads or microprisms in the vinyl are designed to refract and internally reflect light. When light enters the vinyl, it changes direction as it passes through the material due to the difference in refractive index between the vinyl and the beads/prisms. This refraction helps direct the light towards the reflective layer on the backside of the vinyl.

3. Reflective Layer: Heat transfer reflective vinyl typically has a metallic or reflective layer on its backside. This layer acts as a mirror, reflecting the light back to its source. It plays a crucial role in enhancing visibility, especially in low-light conditions or when illuminated by artificial light sources.

4. Angle of Incidence: The effectiveness of heat transfer reflective vinyl depends on the angle at which light hits the material. Retroreflection is most efficient when light approaches the vinyl at a near perpendicular angle. This property ensures that the reflected light is directed back towards the original source, such as a vehicle’s headlights or a flashlight.

By leveraging these principles of retroreflection, refraction, and reflective layers, heat transfer reflective vinyl maximizes its ability to reflect light, making it highly visible and increasing safety in various applications such as road signs, high-visibility apparel, and promotional materials.

Exploring Different Applications of Heat Transfer Reflective Vinyl

Heat transfer reflective vinyl finds applications in various industries and creative endeavors. Here are some different applications of heat transfer reflective vinyl:

1. Road and Traffic Safety

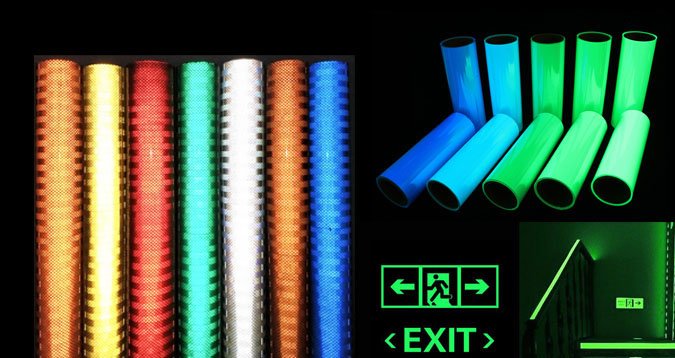

Heat transfer reflective vinyl is widely used in the manufacturing of road signs, traffic cones, barricades, and other traffic safety equipment. Its reflective properties enhance visibility, especially during nighttime or low-light conditions, improving road safety.

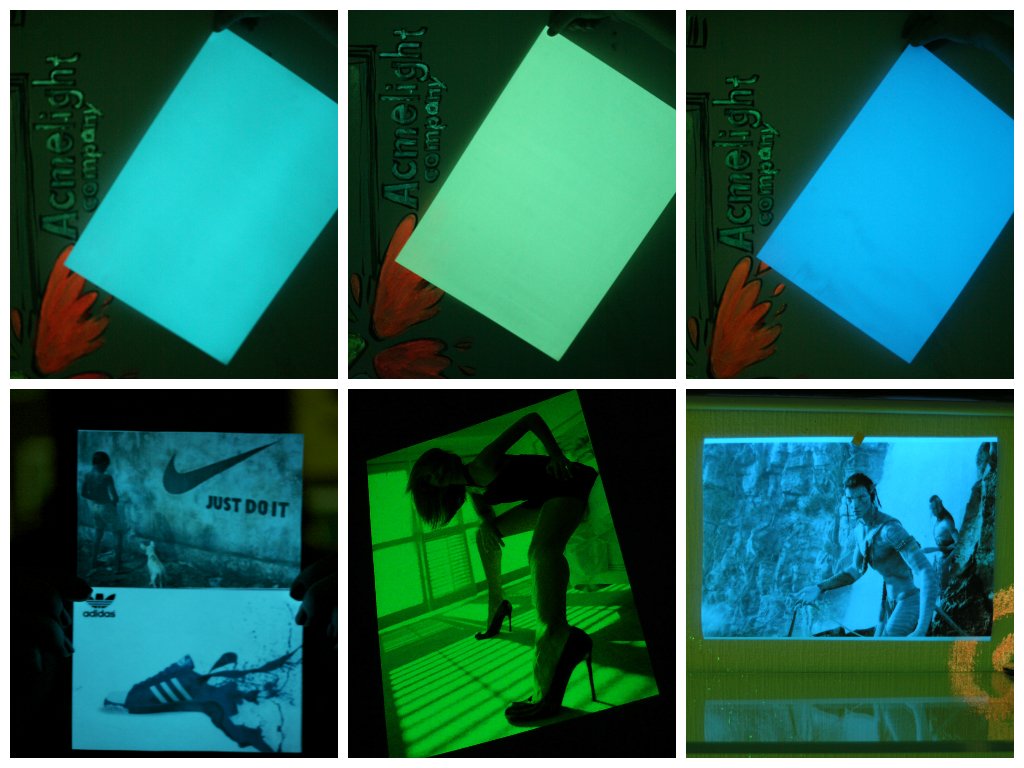

2. Apparel and Fashion

Heat transfer reflective vinyl is utilized in the fashion industry to create trendy and reflective clothing items. It can be applied to t-shirts, jackets, hats, shoes, and other garments, adding a touch of style while increasing visibility during nighttime activities or in dimly lit environments.

3. Sports and Outdoor Gear

Many sports and outdoor gear manufacturers incorporate heat transfer reflective vinyl into their products. It can be found on athletic apparel, shoes, backpacks, helmets, and accessories, enhancing visibility and safety during outdoor activities such as running, cycling, hiking, and camping.

4. Personal Protective Equipment (PPE)

Heat transfer reflective vinyl is used in the production of various types of PPE, including safety vests, jackets, coveralls, and helmets. The reflective properties help workers remain visible and safe in hazardous environments or during nighttime operations.

5. Promotional Products

Heat transfer reflective vinyl is utilized in the creation of promotional items and merchandise. It can be applied to bags, caps, keychains, stickers, and other promotional materials, allowing businesses to increase brand visibility and promote safety simultaneously.

6. Signage and Advertising

Heat transfer reflective vinyl is employed in the signage and advertising industry. It is used to create eye-catching banners, vehicle graphics, window decals, and outdoor signs that are visible both during the day and at night, capturing attention and promoting safety.

7. Customized Gifts and Accessories

Individuals often use heat transfer reflective vinyl to personalize gifts and accessories. It can be applied to mugs, phone cases, notebooks, wallets, and other items, making them unique and adding a reflective element.

8. Emergency and Rescue Equipment

Heat transfer reflective vinyl is essential in emergency and rescue equipment manufacturing. It is applied to the gear worn by firefighters, paramedics, police officers, and other emergency responders to enhance visibility and ensure their safety during critical operations.

These are just a few examples of the diverse applications of heat transfer reflective vinyl. Its versatility and reflective properties make it a valuable material in various industries, enhancing both design aesthetics and safety.

(Click the picture to get the products)

Final Words

In conclusion, heat transfer reflective vinyl is truly revolutionizing the worlds of design and safety. With its remarkable reflective properties, this versatile material has found its way into a wide range of applications across industries. From enhancing visibility on road signs and traffic safety equipment to adding a touch of style to apparel and fashion, heat transfer reflective vinyl combines creativity with functionality. Its ability to increase visibility during low-light conditions has made it an essential component in personal protective equipment and emergency gear, ensuring the safety of workers and first responders.

As we continue to explore the possibilities of this remarkable material, we can look forward to even more innovative and exciting applications that will further elevate the realms of design and safety. So, embrace the power of heat transfer reflective vinyl and unlock a world of endless possibilities where style and safety intertwine.