The Basics of Orange Reflective Vinyl: A Comprehensive Introduction

Orange reflective vinyl has become a popular choice for a wide range of applications, from safety signage and vehicle graphics to creative design projects. This versatile material not only adds a vibrant pop of color to surfaces but also enhances visibility and safety in various settings. Whether you’re looking to transform a dull surface or increase the visibility of your branding, understanding the basics of orange reflective vinyl is crucial.

So, let’s embark on a journey to discover the wonders of orange reflective vinyl and unlock its potential to transform surfaces into dazzling showcases of both style and safety.

Exploring the Versatility of Orange Reflective Vinyl for Surface Transformation

Orange reflective vinyl offers a remarkable level of versatility when it comes to surface transformation. Here are some key aspects that highlight its versatility:

1. Enhancing Visibility

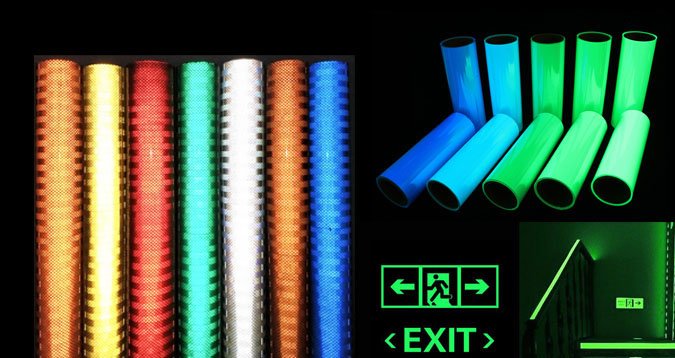

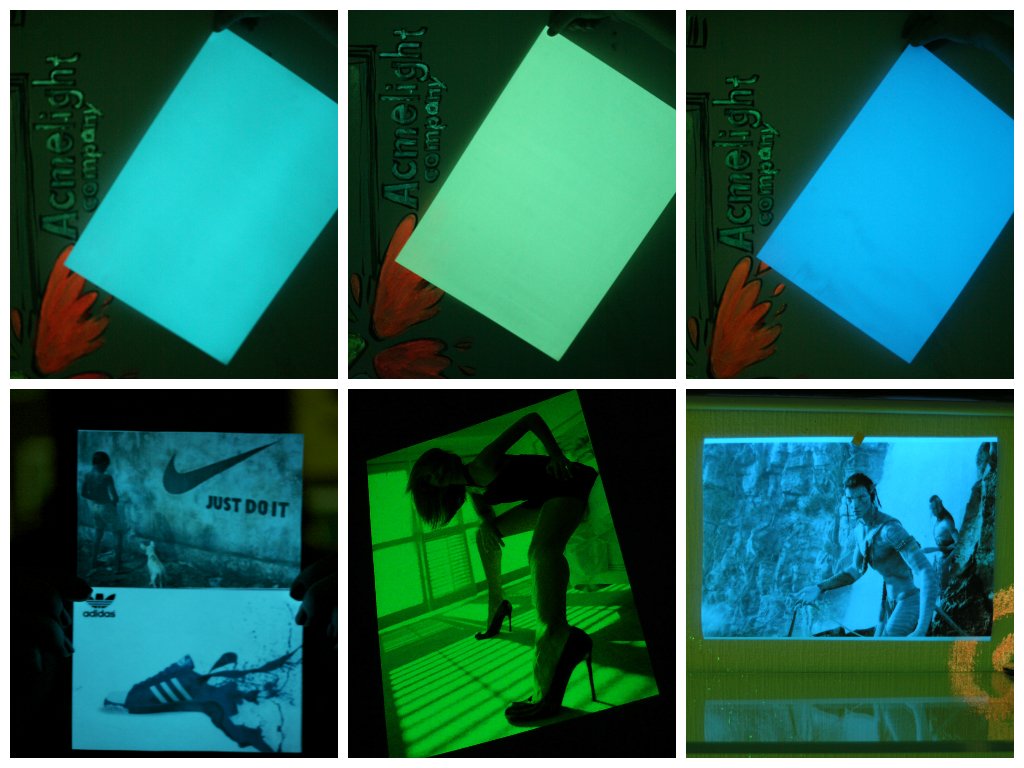

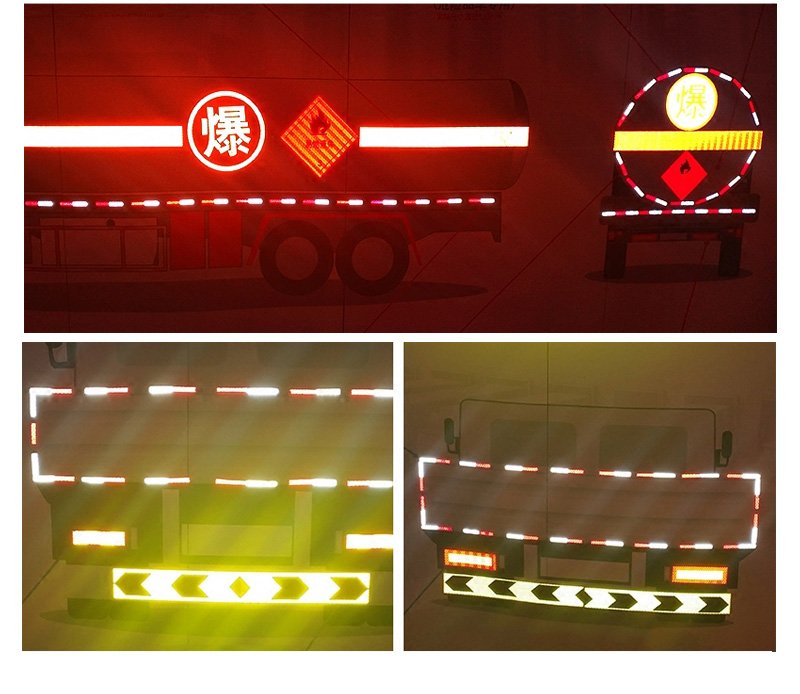

Orange reflective vinyl is primarily used to increase visibility and safety in various applications. It can be applied to different surfaces, including vehicles, signs, equipment, clothing, and accessories. By transforming these surfaces with orange reflective vinyl, they become highly visible, especially in low-light conditions or when illuminated by headlights or other light sources.

2. Creative Design Possibilities

Beyond its practical use, orange reflective vinyl opens up a world of creative design possibilities. It can be cut into different shapes, letters, or graphics, allowing for unique and eye-catching designs. Whether it’s for signage, artwork, or branding purposes, the versatility of orange reflective vinyl empowers designers and creators to make a bold statement.

3. Surface Compatibility

Orange reflective vinyl adheres well to various surfaces, including metal, plastic, glass, fabric, and more. This versatility enables it to be applied to a wide range of objects and materials. Whether you want to transform a vehicle, a safety cone, or even a garment, orange reflective vinyl provides a reliable solution.

4. Outdoor Durability

Orange reflective vinyl is engineered to withstand outdoor conditions. It is typically resistant to UV rays, weathering, and fading, ensuring that the vibrant orange color and reflective properties remain intact over time. This durability makes it suitable for long-term applications, even in challenging environments.

5. Customization Options

Many manufacturers offer orange reflective vinyl in different shades, finishes, and patterns. This allows for customization according to specific requirements and preferences. Whether you prefer a glossy or matte finish or want a specific shade of orange, there are options available to achieve the desired effect.

6. Temporary or Permanent Application

Orange reflective vinyl can be used for both temporary and permanent applications. It can be easily applied and removed without leaving adhesive residue on the surface. This flexibility makes it ideal for temporary signage, promotions, or seasonal decorations.

In summary, the versatility of orange reflective vinyl lies in its ability to enhance visibility, its compatibility with various surfaces, its creative design possibilities, its outdoor durability, its customization options, and its suitability for both temporary and permanent applications. These qualities make it a versatile material for transforming surfaces while adding a vibrant and safety-enhancing element.

Step-by-Step Guide: Applying Orange Reflective Vinyl to Different Surfaces

Step 1: Gather the necessary materials

- Orange reflective vinyl sheets

- Surface cleaner (such as isopropyl alcohol)

- Squeegee or application tool

- Cutting tools (scissors or precision knife)

- Measuring tape or ruler

- Masking tape (optional)

Step 2: Prepare the surface

- Clean the surface thoroughly using a surface cleaner to remove any dust, dirt, or grease. This will ensure proper adhesion of the vinyl.

Step 3: Measure and cut the vinyl

- Measure the area where you want to apply the orange reflective vinyl. Add some extra allowance for adjustments and trimming.

- Transfer the measurements to the backside of the vinyl sheet using a pencil or marker.

- Carefully cut the vinyl along the marked lines using scissors or a precision knife. Ensure smooth and precise cuts.

Step 4: Peel and align the vinyl

- Peel off a small portion of the backing paper from the vinyl, exposing the adhesive side.

- Align the exposed portion of the vinyl with the desired location on the surface. Use masking tape to hold it in place temporarily if needed.

Step 5: Apply the vinyl

- Once the vinyl is aligned, slowly and evenly peel off the backing paper while pressing down the vinyl onto the surface.

- Use a squeegee or application tool to smooth out any air bubbles or wrinkles as you go. Start from the center and work your way towards the edges.

- Continue peeling off the backing paper and pressing down the vinyl, using the squeegee to ensure proper adhesion. Take your time to avoid mistakes.

Step 6: Trim and finish

- Once the entire vinyl sheet is applied, use a precision knife or scissors to trim any excess vinyl along the edges or corners for a neat and clean finish.

- Go over the applied vinyl with the squeegee again to ensure strong adhesion and smoothness.

- Allow the vinyl to set and cure as per the manufacturer’s instructions. Avoid exposing it to moisture or extreme conditions during this period.

Step 7: Inspect and make adjustments

- Carefully inspect the applied vinyl for any air bubbles, wrinkles, or imperfections. If you notice any, use the squeegee to smooth them out or make necessary adjustments.

Congratulations! You have successfully applied orange reflective vinyl to the desired surface. Remember to follow the manufacturer’s guidelines and recommendations for the specific vinyl product you are using.

Final Words

In conclusion, orange reflective vinyl holds the power to transform dull surfaces into captivating focal points that demand attention. With its vibrant hue and light-reflective properties, this versatile material not only enhances safety and visibility in high-traffic areas but also offers endless creative possibilities for designers and DIY enthusiasts. By following the step-by-step guide outlined in this article, you can confidently apply orange reflective vinyl to various surfaces, whether it’s for decorative purposes, advertising, or safety signage. Embrace the brilliance of orange reflective vinyl and unlock a world of possibilities, where surfaces come alive with a dazzling and vibrant glow that leaves a lasting impression. Let your imagination soar and create eye-catching designs that captivate both day and night, while elevating the aesthetics and functionality of your surroundings. Experience the transformative power of orange reflective vinyl and witness surfaces go from dull to truly dazzling.