How red reflective vinyl enhances visibility at night

Red reflective vinyl enhances visibility at night through a combination of reflective technology and the color red itself.

1. Reflective Technology

Red reflective vinyl is designed with retroreflective properties. This means that when light from a source, such as headlights, it reflects the light back towards its source rather than scattering it in all directions like a regular surface. This directed reflection allows the light to reach the eyes of the viewer, making the object or surface highly visible even in low-light conditions.

2. Microprismatic Design

Red reflective vinyl often utilizes a microprismatic design, consisting of tiny prisms or microbeads that are arranged in a specific pattern. These microprisms are strategically positioned to reflect light efficiently and effectively. As a result, the reflected light is intensified, making the red vinyl highly visible and increasing its overall brightness.

3. Red Color Advantage

The color red itself is naturally attention-grabbing and stands out against many backgrounds. In terms of visibility, red is particularly effective because it has a longer wavelength compared to other colors in the visible spectrum. This longer wavelength allows red objects to be seen from a greater distance, making them more noticeable and aiding in quick identification, especially in low-light situations.

Best practices for applying red reflective vinyl on different surfaces

1. Surface Preparation

Ensure that the surface where you will be applying the red reflective vinyl is clean, dry, and free from any dirt, dust, grease, or other contaminants. Use a mild detergent or surface cleaner to clean the surface thoroughly and allow it to dry completely before proceeding.

2. Temperature Considerations

Check the temperature requirements specified by the manufacturer for applying the red reflective vinyl. In general, it’s best to apply the vinyl in moderate temperatures, usually between 50°F and 90°F (10°C and 32°C). Extreme cold or heat can affect the adhesive properties and make the application more challenging.

3. Tools and Equipment

Gather the necessary tools and equipment for the application process, which may include a squeegee, masking tape, a measuring tape or ruler, a cutting tool (such as a utility knife or scissors), and a heat gun or hairdryer (if required by the vinyl).

4. Test Application

Before applying the red reflective vinyl to the entire surface, perform a test application on a small, inconspicuous area to ensure that it adheres properly and does not cause any damage or discoloration.

5. Proper Alignment

Carefully plan and measure the placement of the red reflective vinyl to ensure proper alignment and positioning. Use masking tape to mark reference points or create a temporary guide for accurate placement.

6. Peel-and-Stick Method

Most red reflective vinyl comes with a backing paper that you need to peel off before applying. Start peeling the backing paper gradually while smoothing the vinyl onto the surface using a squeegee or your fingers. Work slowly and avoid trapping air bubbles underneath.

7. Applying Heat (If Required)

Some red reflective vinyl may require the use of heat to activate the adhesive and ensure better adhesion. Use a heat gun or hairdryer on a low setting to gently warm the vinyl while applying pressure with the squeegee to help it conform to the surface.

8. Trim Excess Vinyl

Once the red reflective vinyl is applied, use a cutting tool to trim any excess vinyl carefully. Pay attention to corners, curves, and edges to achieve a clean and professional-looking finish.

9. Post-Application Care

After applying the red reflective vinyl, avoid washing or exposing it to water for at least 24 to 48 hours to allow the adhesive to fully bond with the surface. Follow any additional care instructions provided by the manufacturer to maintain the longevity of the vinyl.

Always refer to the specific instructions provided by the manufacturer of the red reflective vinyl you are using, as different products may have unique application guidelines.

Exploring the durability and weather resistance of red reflective vinyl

Red reflective vinyl is known for its durability and weather resistance, making it a popular choice for various applications. Here are some key points regarding its durability and weather resistance:

1. Durability: Red reflective vinyl is designed to withstand harsh environmental conditions and maintain its performance over time. It is typically made from high-quality materials that are resistant to tearing, peeling, and fading.

2. UV Resistance: Red reflective vinyl is often treated with UV inhibitors, which help protect it from the damaging effects of sunlight exposure. This UV resistance ensures that the red color and reflective properties of the vinyl remain vibrant and effective for an extended period.

3. Water Resistance: Red reflective vinyl is generally water-resistant or even waterproof, depending on the specific product and manufacturer. It can withstand exposure to rain, snow, and other forms of moisture without losing its reflective qualities or deteriorating.

4. Temperature Resistance: Red reflective vinyl is engineered to withstand a wide range of temperatures. It can endure both hot and cold climates without cracking, warping, or losing adhesion.

5. Chemical Resistance: In many cases, red reflective vinyl has good resistance to chemicals and solvents commonly encountered in various environments. This resistance helps protect the vinyl from damage or degradation when exposed to certain substances.

It’s important to note that the specific durability and weather resistance of red reflective vinyl can vary depending on the manufacturer and product quality. When selecting red reflective vinyl for a particular application, it’s advisable to review product specifications, certifications, and customer reviews to ensure it meets the desired durability and weather resistance requirements.

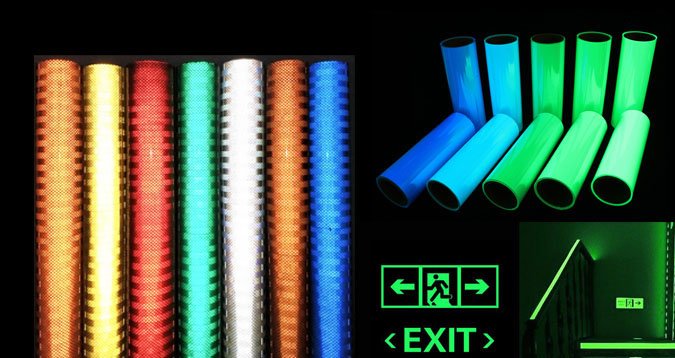

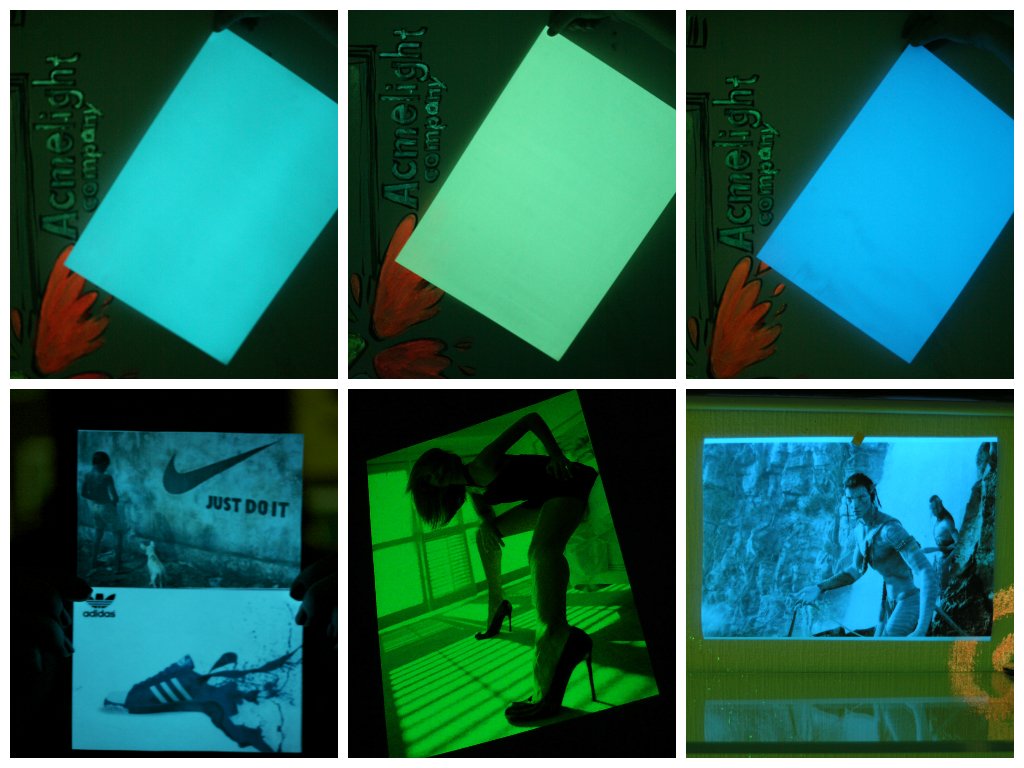

(Click the picture to get the products)

Final Words

In conclusion, red reflective vinyl proves to be an invaluable tool for enhancing visibility in various applications. Its durability, weather resistance, and impressive reflective properties make it a reliable choice for safety, style, and functionality. Whether it’s used for road signs, personal safety gear, vehicle wraps, or DIY projects, red reflective vinyl offers a vibrant and eye-catching solution that helps ensure visibility, even in low-light conditions.

By understanding its science, application techniques, and the diverse range of possibilities it offers, you can harness the power of red reflective vinyl to elevate safety, add a touch of flair, and make a lasting impact. Embrace the potential of this remarkable material and unlock a world of enhanced visibility with red reflective vinyl. Stay seen, stay safe, and let your brilliance shine through.