The Science Behind Reflective Vinyl Rolls: How They Work

Reflective vinyl rolls utilize a combination of advanced materials and engineering principles to achieve their distinctive reflective properties. The science behind how they work involves the interaction between light and microscopic glass beads or prismatic elements embedded within the vinyl.

Here’s a breakdown of the science behind reflective vinyl rolls:

1. Retroreflection

Retroreflection is the phenomenon where light rays are returned in the direction they originated. Reflective vinyl rolls are designed to maximize retroreflection. When light strikes the surface of the vinyl, it encounters thousands of tiny glass beads or prisms. These elements are strategically placed in a way that redirects the light back to its source, such as a vehicle’s headlights or a camera flash.

2. Microscopic Glass Beads or Prisms

Reflective vinyl rolls contain microscopic glass beads or prisms that are evenly distributed across the surface. These elements have a high refractive index, meaning they bend light as it passes through them. When light enters the vinyl, it travels through the transparent layer and encounters the glass beads or prisms. The light rays then bounce off the reflective surface of the beads or prisms, changing direction and returning back towards the light source.

3. Total Internal Reflection

Total internal reflection is a key principle at play in reflective vinyl rolls. It occurs when light traveling from a medium with a higher refractive index (such as glass beads) encounters a medium with a lower refractive index (such as air). The light rays striking the reflective surface at certain angles undergo total internal reflection, bouncing back within the vinyl rather than escaping into the air. This property ensures efficient retroreflection and enhances the visibility of the vinyl.

4. Angle of Incidence

The angle at which light strikes the surface of the vinyl affects the intensity of the retroreflection. Reflective vinyl rolls are designed to optimize the angle of incidence, ensuring that light is reflected back towards its source even at different viewing angles. This characteristic is crucial for maintaining visibility in various lighting conditions and viewing perspectives.

5. Wavelength Selectivity

Reflective vinyl rolls are engineered to reflect specific wavelengths of light, particularly those within the visible spectrum. By selectively reflecting certain colors, they enhance contrast and make the surface more visible, even in low-light conditions. This property is particularly important for road signs, vehicle graphics, and other safety applications.

In summary, reflective vinyl rolls work by utilizing microscopic glass beads or prisms to redirect light back towards its source through retroreflection. The strategic placement of these elements, coupled with the principles of total internal reflection and wavelength selectivity, maximizes visibility and enhances safety in a variety of applications.

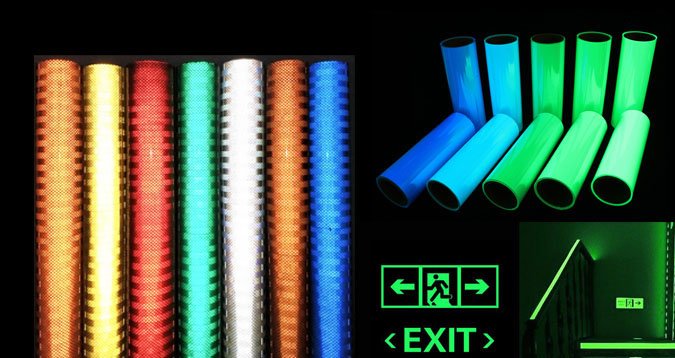

Different Types of Reflective Vinyl Rolls and Their Applications

- Engineer Grade Reflective Vinyl Rolls: This type of reflective vinyl is commonly used for traffic signs, road markings, and reflective decals. It provides excellent visibility and durability for outdoor applications.

- High-Intensity Grade Reflective Vinyl Rolls: High-intensity grade reflective vinyl offers enhanced visibility and is commonly used for road signs, construction signs, vehicle graphics, and emergency vehicle markings. It provides superior reflectivity, even in low-light conditions.

- Diamond Grade Reflective Vinyl Rolls: Diamond grade reflective vinyl is the highest level of retroreflective material. It is primarily used for highway signs, traffic cones, and other safety devices that require maximum visibility. It offers exceptional reflectivity and is highly durable.

- Prismatic Reflective Vinyl Rolls: Prismatic reflective vinyl rolls are designed for high-impact visibility and are often used in traffic signs, safety apparel, and reflective tapes. They provide excellent reflective performance and are available in various colors.

- Commercial Reflective Vinyl Rolls: Commercial grade reflective vinyl is commonly used for advertising purposes, such as storefront displays, banners, and promotional signage. It offers good reflectivity while allowing for creative designs and branding opportunities.

- Reflective Heat Transfer Vinyl Rolls: Reflective heat transfer vinyl is ideal for customizing apparel, such as t-shirts, jackets, and sportswear. It can be easily applied using a heat press machine and provides reflective properties for added visibility during nighttime activities.

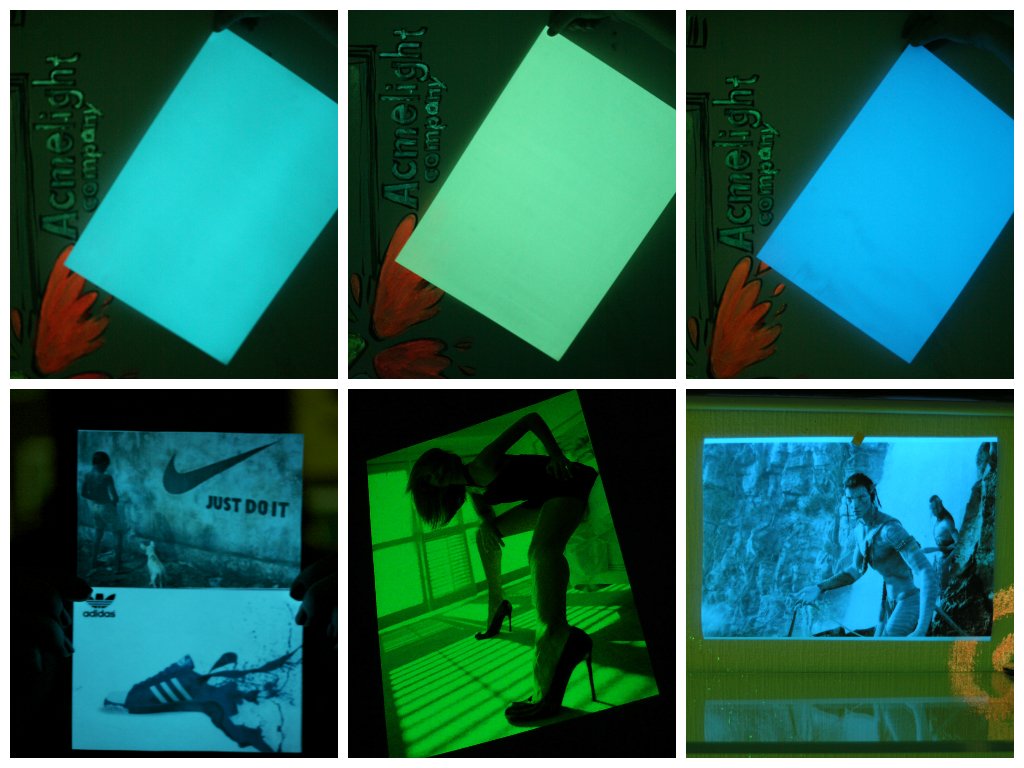

- Reflective Vinyl Rolls for Decorative Purposes: Reflective vinyl rolls are also available in decorative options, offering a range of colors, patterns, and textures. They can be used for interior design projects, wall decals, art installations, and creative crafts.

These different types of reflective vinyl rolls cater to various applications and requirements, ensuring increased visibility, safety, and customization options across different industries and creative projects.

Final Words

In conclusion, reflective vinyl rolls have emerged as a transformative tool, turning ordinary surfaces into captivating masterpieces that command attention. Whether you’re looking to enhance road safety, create eye-catching signage, add a touch of brilliance to your interior design, or embark on creative DIY projects, reflective vinyl rolls offer a multitude of possibilities. With their remarkable reflectivity, durability, and versatility, these rolls empower you to unlock your creativity and make a lasting impact. So, embrace the power of reflective vinyl rolls, explore their endless applications, and let your imagination shine through as you transform the ordinary into extraordinary, one surface at a time. Let the radiance and allure of reflective vinyl rolls illuminate your world.