Reflective Sheeting

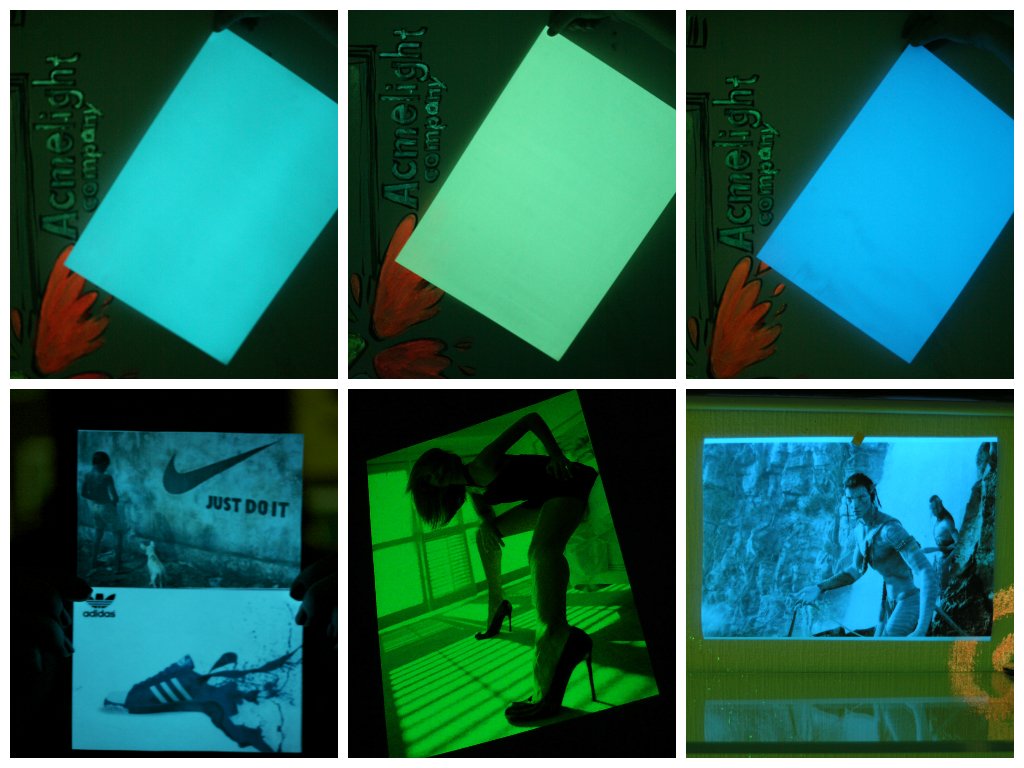

Sino Group is a professional reflective film manufacturer and wholesale supplier, kindly get factory price of: of reflective sheeting, reflective tape, photoluminescent film glow in dark , road safety reflective materials.

Collections

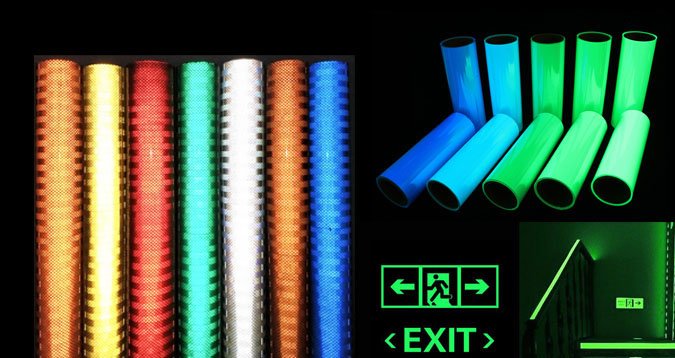

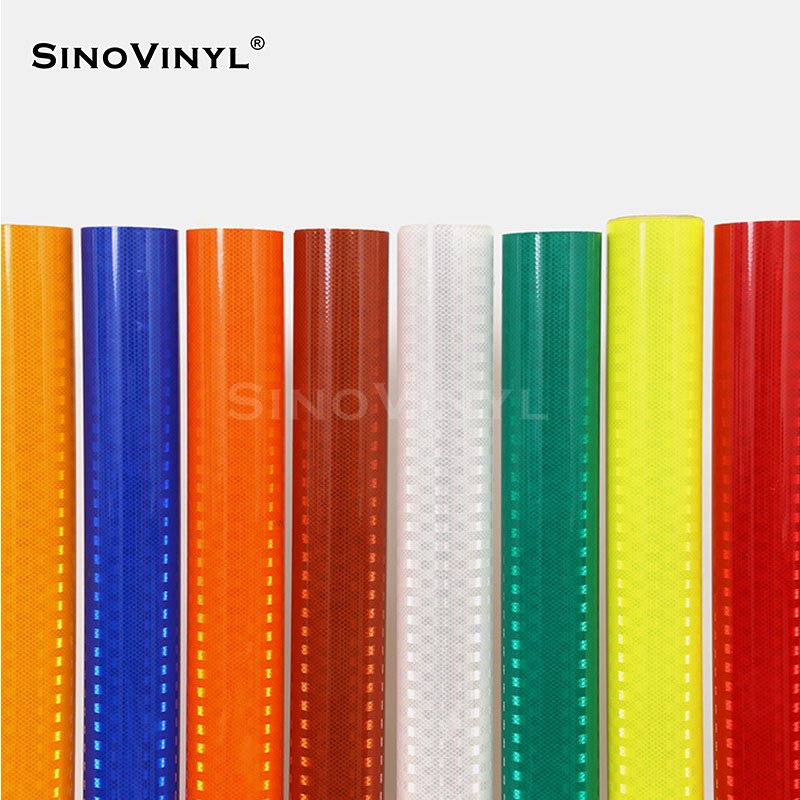

PET 3100 Reflective Sheeting

Acrylic 3200 Reflective Vinyl Sheeting

Diamond HIP

EGP 610C Reflective Vinyl Material

Reflective sheeting is often composed of multiple layers that work in combination to achieve its reflective properties. These layers typically include a retroreflective layer, a protective cover layer, and an adhesive backing. Here’s a breakdown of each layer’s role:

1. Retroreflective Layer

The core feature of reflective sheeting is the retroreflective layer. These glass beads or prisms are strategically designed to bounce light back towards its source, regardless of the angle at which the light hits the surface.

2. Protective Cover Layer

The cover layer is usually transparent and serves to preserve the reflective properties of the underlying retroreflective materials.

3. Adhesive Backing

The adhesive layer on the back of reflective sheeting allows it to be easily applied to various surfaces, such as signs, vehicles, clothing, helmets, road barriers, and more.

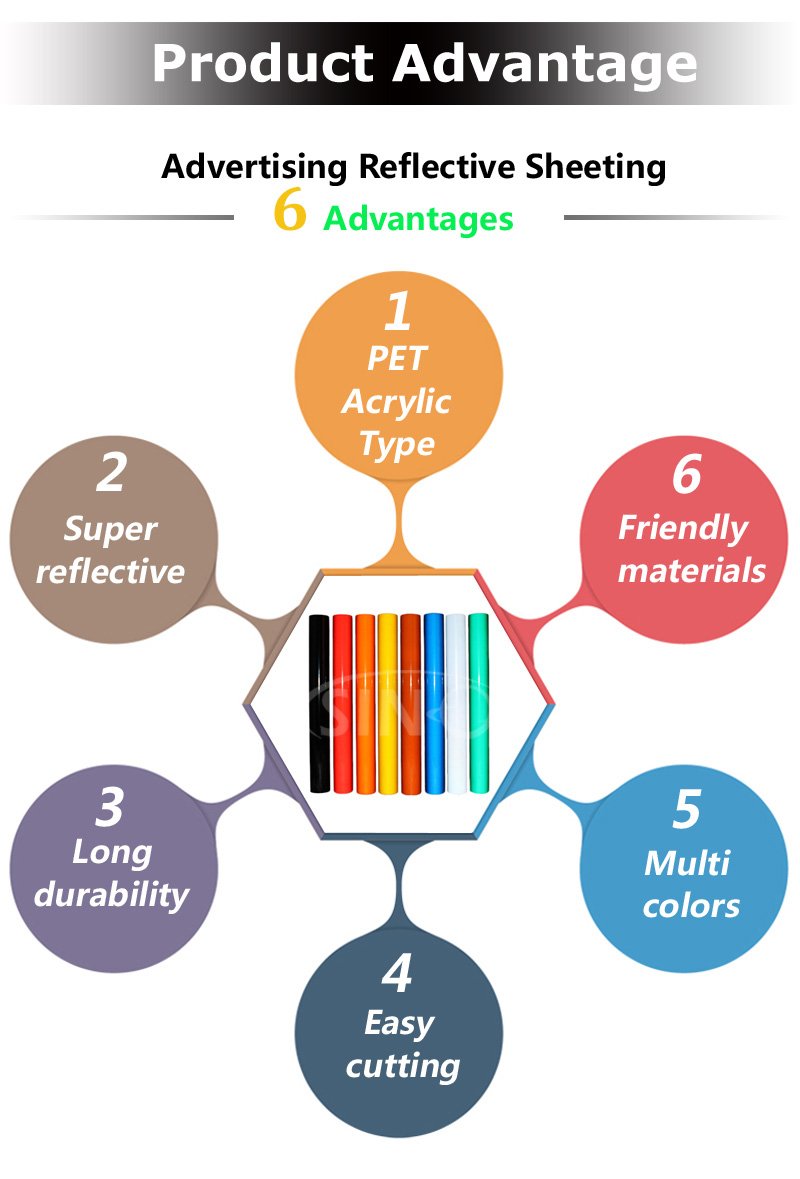

Some common types of reflective sheeting include:

1. Engineering Grade

This type of sheeting is commonly used for traffic signs, delineators, and other traffic control devices.

2. High-Intensity Prismatic Grade

High-intensity prismatic sheeting provides enhanced visibility and performance compared to engineering grade sheeting.

3. Diamond Grade

Diamond grade sheeting is the highest level of retroreflectivity and is often used for critical situations like emergency vehicles, highway signs, and areas with complex or challenging traffic patterns.

Factory Show of SINO VINYL: Reflective Material Supplier

Gluing Machine

Quality Control Machine

Raw Material Warehouse

Shipping Loading Cotainer

Showroom of SINO VINYL: Perfect Graphics Solutions