Safety Benefits of Reflective Vinyl Wraps

Here are the safety benefits of reflective vinyl wraps that you can include in your blog post:

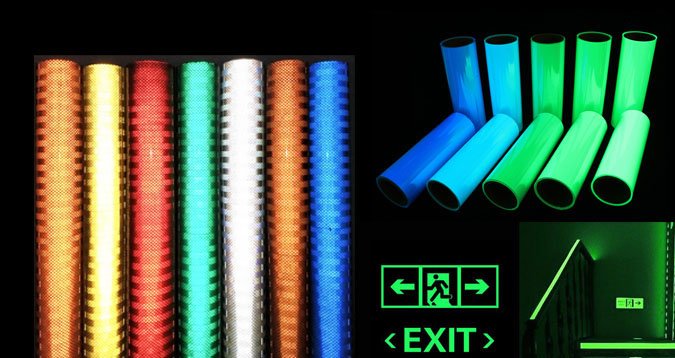

1. Enhanced Visibility in Low Light Conditions:

– Reflective vinyl wraps are designed to reflect light, making them highly visible even in low light or nighttime conditions.

– This increased visibility ensures that vehicles or objects wrapped in reflective vinyl are easily spotted by other drivers, pedestrians, and cyclists.

2. Contribution to Road Safety:

– Reflective vinyl wraps play a crucial role in overall road safety by reducing the risk of accidents, especially in situations where visibility is compromised.

3. Accident Prevention and Awareness:

– Reflective vinyl wraps actively contribute to accident prevention by giving drivers more time to react to potential hazards on the road.

– Their high visibility ensures that other road users are aware of the presence and movements of vehicles or objects wrapped in reflective material.

4. Increased Visibility for Emergency and Service Vehicles:

– Reflective vinyl wraps are widely used on emergency vehicles, such as police cars, ambulances, and fire trucks, to maximize their visibility during emergency responses.

– This quick and clear identification of emergency vehicles helps them navigate through traffic more safely and efficiently.

5. Reduced Risk of Rear-End Collisions:

– Reflective wraps on the rear of vehicles, including cars, trucks, and trailers, significantly reduce the likelihood of rear-end collisions.

– The high reflectivity alerts drivers behind them to slow down or maintain a safe distance, especially in situations where sudden stops might occur.

6. Improved Safety for Pedestrians and Cyclists:

– Reflective wraps are not limited to vehicles alone.

7. Enhanced Safety for Work Zones:

– Reflective vinyl wraps are commonly applied to construction vehicles and equipment, creating a safer work environment in construction zones and on roadways where maintenance or repairs are being conducted.

Durability and Longevity

Let’s dive into the topic of “Durability and Longevity” of reflective vinyl wraps.

Materials Used in Reflective Wraps:

Reflective vinyl wraps are typically made from high-quality materials designed to withstand various environmental conditions. These materials often include:

1. Vinyl Films:

Reflective wraps are primarily constructed from vinyl films. These films are engineered to be durable, weather-resistant, and capable of adhering securely to different surfaces.

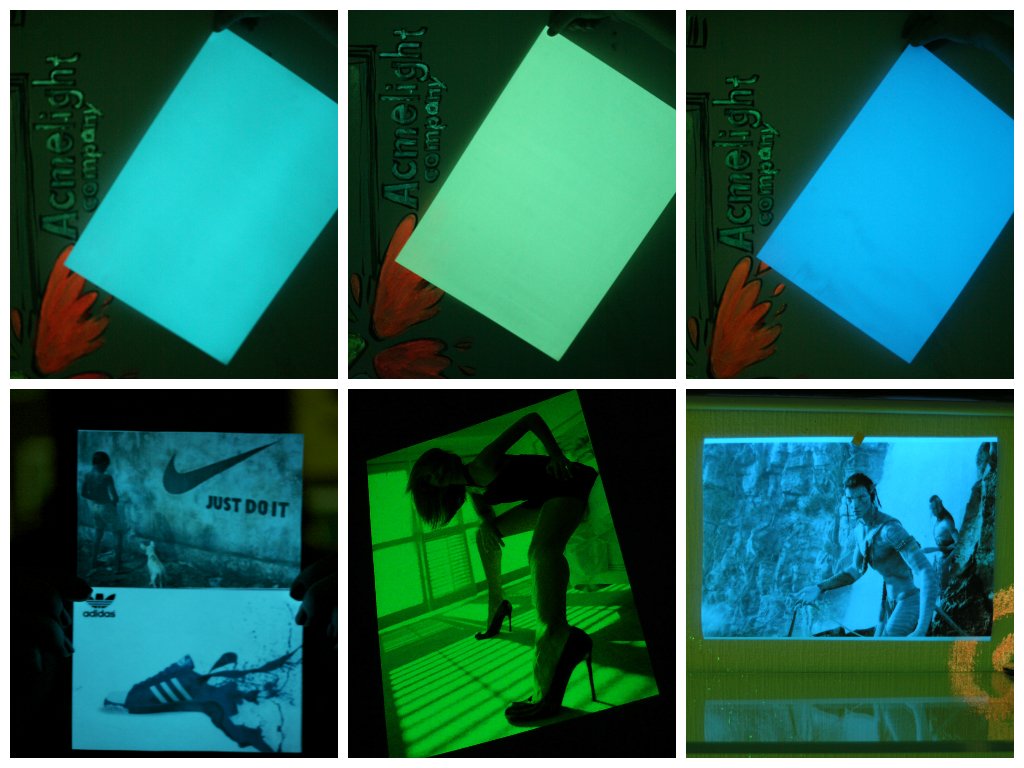

2. Reflective Layer:

The core feature of these wraps is the reflective layer. This layer is made up of tiny glass beads or microprisms that have the ability to reflect light back towards its source. This ensures high visibility in low-light conditions.

3. Adhesive Backing:

A strong adhesive backing is applied to the vinyl film to ensure a secure and long-lasting bond with the surface it’s applied to.

4. Protective Coating (Optional):

Some reflective wraps come with an additional protective layer or coating. This coating can enhance durability by providing resistance against UV rays, abrasions, and chemical exposure.

How Long Can You Expect a Wrap to Last?

The lifespan of a reflective vinyl wrap can vary depending on several factors:

1. Quality of Materials:

High-quality vinyl films and reflective layers tend to have a longer lifespan compared to lower-grade materials.

2. Installation Quality:

Proper installation by a skilled professional or a meticulous DIY job can significantly extend the life of the wrap.

3. Environmental Conditions:

Exposure to harsh weather conditions, such as extreme heat, cold, or prolonged UV exposure, can affect the longevity of the wrap.

4. Surface Preparation:

A well-prepared surface, free of dirt, debris, and contaminants, ensures better adhesion and, consequently, a longer lifespan.

5. Usage and Maintenance:

How the vehicle or object is used and maintained also plays a role. Regular cleaning and avoiding abrasive materials during cleaning can help preserve the wrap.

Maintenance Tips for Maximum Lifespan:

1. Gentle Cleaning:

Wash the wrapped surface with a mild soap and water solution using a soft sponge or cloth. Avoid abrasive materials or harsh chemicals.

2. Avoid High-Pressure Washing:

High-pressure washers can potentially damage the wrap. If using a pressure washer, keep it at a low setting and maintain a safe distance.

3. Protect from Harsh Chemicals:

Avoid using harsh chemicals or solvents on the wrap, as they can degrade the material.

4. Inspect for Damage:

Regularly inspect the wrap for any signs of damage, such as peeling edges or scratches. Promptly address any issues to prevent further deterioration.

5. Store Indoors (If Possible):

If the wrapped object or vehicle is not in use for an extended period, storing it indoors can protect the wrap from extreme weather conditions.

By following these maintenance tips and considering the factors that affect lifespan, you can maximize the durability and longevity of your reflective vinyl wrap, ensuring it remains vibrant and effective for an extended period.