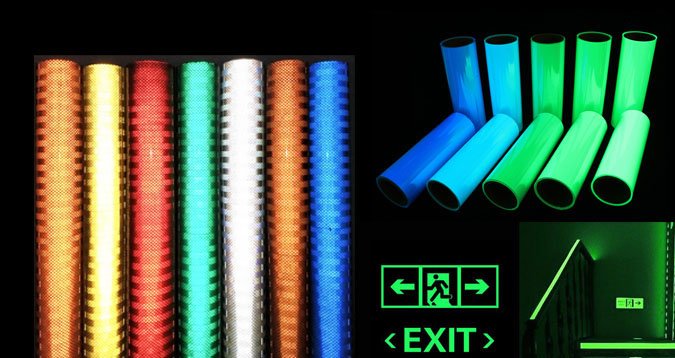

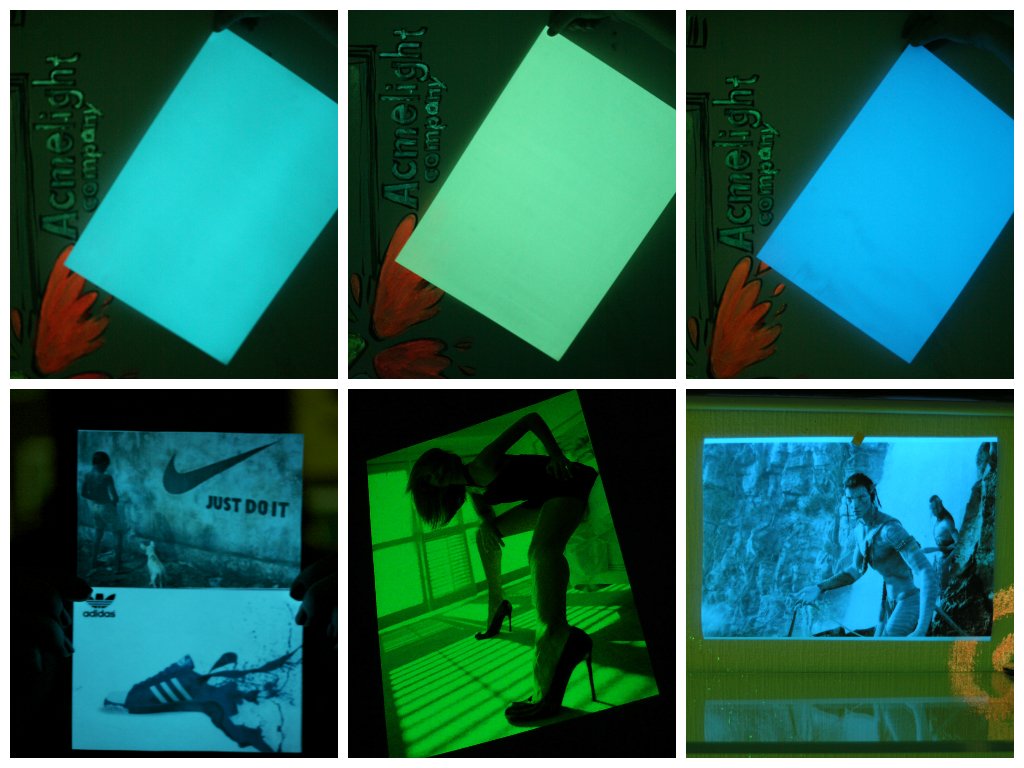

Reflective vinyl adhesive has been a game-changer for workplaces and businesses that need to enhance safety and visibility. Its high-reflectivity properties enable it to stand out in low visibility environments. Yet, there are a few things to keep in mind before applying it. In this guide, we will explore the ins and outs of reflective vinyl application and walk you through the specifications to achieve optimal functionality and durability.

The Benefits of Reflective Vinyl Application

Highlight the importance of reflective vinyl application for safety and visibility in workplaces. Utilized in various industries and applications, reflective vinyl has vast benefits. Discuss how its application can reduce accidents or injuries and enhance branding.

Factors to consider when Choosing Reflective Vinyl Material

This section will provide a detailed checklist and factors to consider when choosing the right reflective vinyl material for an application. This includes reflectivity levels, color options, adhesive strength, material durability, and weather resistance. This section will give insights into how to interpret data sheets and what to look for in the technical specifications.

The Application Process

Sure, here are the summarized versions:

1. Preparing the Surface and Materials:

Clean the surface with rubbing alcohol or a non-abrasive cleaner, roughen the surface for rough surfaces, and use a heat gun to soften the vinyl for curved surfaces.

2. Aligning Your Vinyl Material:

Use a tape measure to ensure the right size and shape, create alignment marks, and eliminate the risk of errors.

3. The Application Process:

Use a squeegee for flat surfaces and work slowly for curved surfaces to avoid bubbles or wrinkles.

4. Applying Vinyl Adhesive to Glass Surfaces:

Use a soapy solution, avoid overstretching, and position the vinyl correctly.

5. Applying Vinyl Adhesive to Metal Surfaces:

Clean the surface, work slowly for curved surfaces, and use a squeegee to apply pressure.

6. Mastering Reflective Vinyl Application:

Follow the steps, avoid common mistakes, and achieve high-quality, durable installation.

In conclusion, properly applying reflective vinyl adhesive on different surfaces and materials requires patience, precision, and attention to detail. By following the steps outlined above and avoiding common mistakes, you can achieve a high-quality, durable installation that enhances visibility and safety.

Maintenance and Care

Maintenance of reflective vinyl adhesive is critical for prolonging its lifespan and maximizing its reflective qualities. This section will provide actionable tips on how to protect and maintain your reflective vinyl adhesive to insure long-term durability, easy cleaning, and maximum reflectivity.

Industry Standards

Discuss the importance of adhering to industry standards such as ANSI and OSHA when applying reflective vinyl adhesives. It will explain the requirements for reflectivity levels, color, and design for safety labels, tapes, and signs.

Common Mistakes to Avoid

Reflective vinyl application comes with a few common mistakes that can lead to reduced functionality or durability. This section highlights common mistakes people make when applying reflective vinyl and how to avoid them. Some of these mistakes are choosing the wrong adhesive type based on application, not preparing the surface properly, and not ensuring that the vinyl is installed straight.

Innovative Applications

Showcase some innovative applications of reflective vinyl application across different industries. This can include applications in high traffic construction sites, vehicle wraps, sporting events, and emergency response.

Conclusion:

Reflective vinyl application is essential for businesses looking to prioritize safety and visibility. This guide has provided a detailed and comprehensive overview of what you need to keep in mind before, during, and after applying reflective vinyl adhesive. Ensure that you prioritize getting everything right to enhance functionality and longevity for maximum use.