In the world of visibility and safety, few materials are as significant as reflective sheeting. From the streets we traverse to the clothes we wear during nighttime exercises, this material plays a vital role. Let’s dive deep into the fascinating science behind reflective sheeting and discover why SINOVINYL stands out in this domain.

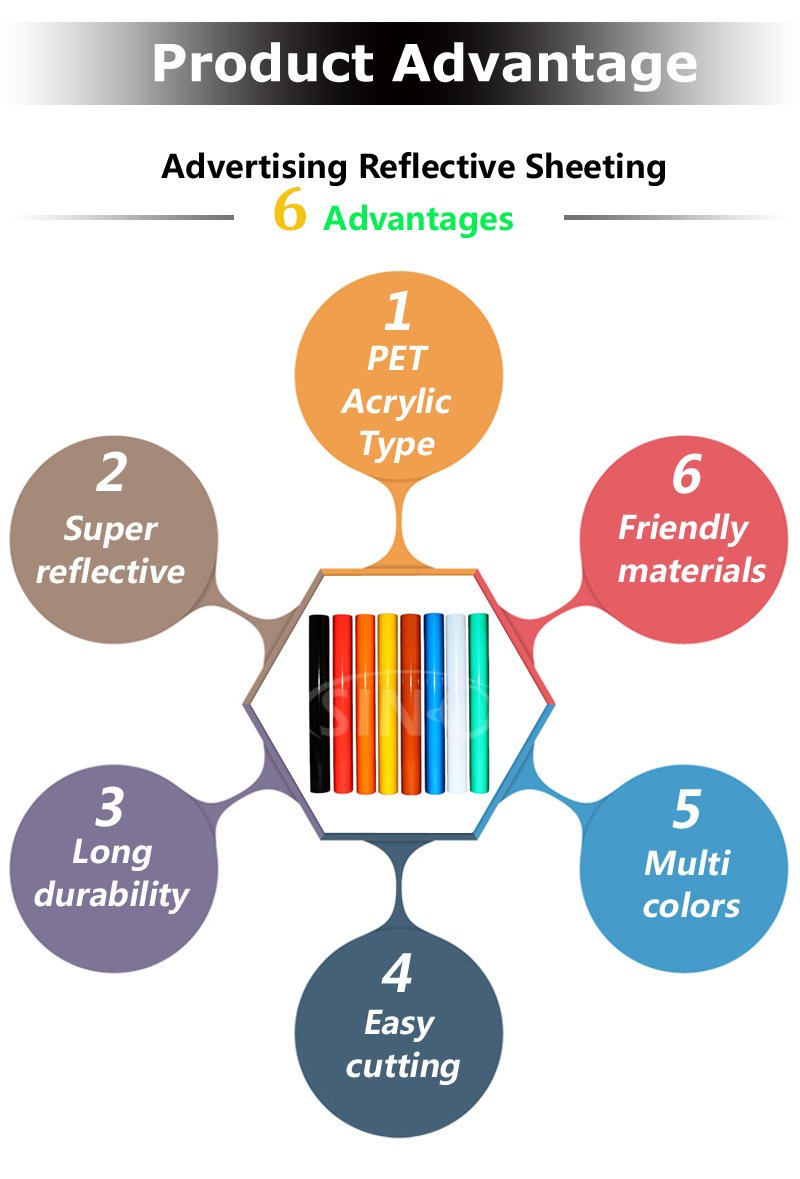

1. The Basics of Reflective Sheeting

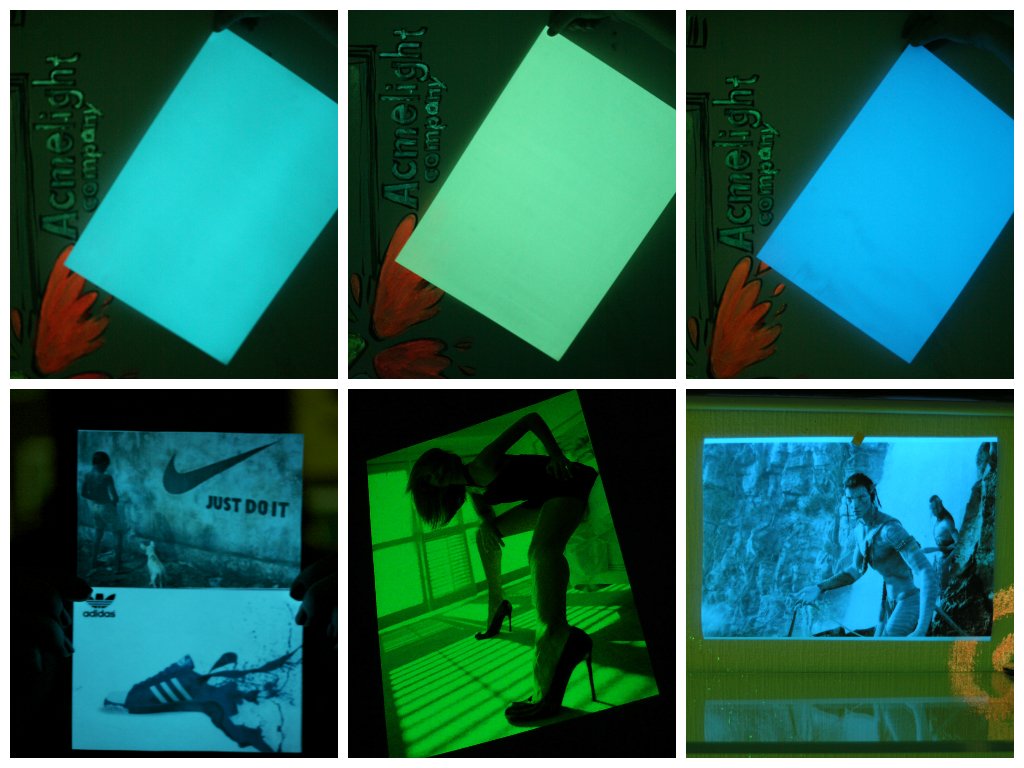

Reflective sheeting, a material engineered to reflect light back to its source, is crucial for visibility and safety.

1.1 Principles of Reflection

Reflection isn’t just about light bouncing back. It’s about light rays returning to the original or close-to-original angle of incidence. This is what makes reflective sheeting distinct – it doesn’t merely scatter light; it directs it purposefully.

1.2 Evolution Over Time

Historically, simple reflective properties were obtained using glass beads. Modern reflective sheeting, however, uses micro-prismatic technology, allowing for a more focused and efficient reflection.

1.3 Categories of Reflectivity

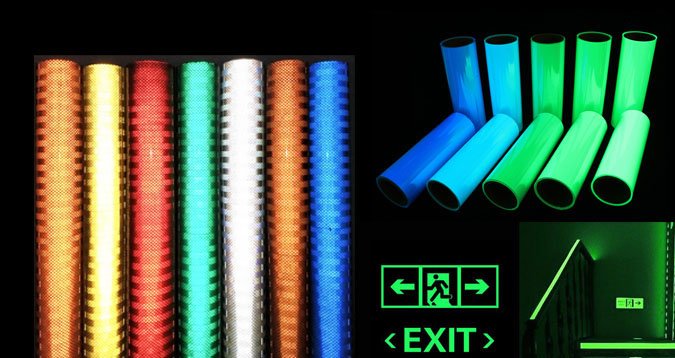

While all reflective sheetings aim to enhance visibility, there are different categories, including engineer grade, high intensity, and diamond grade. Each offers varying degrees of reflectivity suitable for different applications.

1.4 Understanding Retroreflection

Retroreflection, a unique property of certain materials, ensures that light rays return in the direction from which they came. This phenomenon, especially vital for road safety, is a defining feature of quality reflective sheeting like that of SINOVINYL.

2. Practical Applications of Reflective Sheeting

The use of reflective sheeting isn’t limited to just road signs. Its applications are vast and varied.

2.1 Road Safety

Reflective signs, lane markings, and vehicle decals are essential for nighttime driving, helping reduce accidents.

2.2 Sportswear & Gear

From jogging outfits to cycling helmets, reflective sheeting ensures that athletes are visible during their night-time activities.

2.3 Architectural Design

Modern buildings are increasingly integrating reflective elements for both aesthetic appeal and safety.

2.4 Industrial Uses

In warehouses and factories, reflective tape can guide pathways, mark zones, and enhance worker safety.

3. Care and Maintenance of Reflective Sheeting

To maintain the efficiency of reflective sheeting, proper care is essential.

3.1 Cleaning Techniques

Regular cleaning using mild soapy water can help maintain the sheeting’s reflectivity. It’s crucial to avoid abrasive materials which can damage the surface.

3.2 Longevity and Replacement

Though materials like SINOVINYL’s are built for durability, environmental factors can cause wear over time. Regular inspections help determine when replacements are necessary.

3.3 Storage Tips

For unused reflective sheets, it’s vital to store them in a cool, dry place, away from direct sunlight to preserve their quality.

3.4 Recycling and Disposal

As environmental concerns grow, it’s essential to responsibly dispose of or recycle old reflective sheeting, ensuring minimal impact on the planet.

Conclusion

The realm of reflective sheeting is both fascinating and crucial for our modern world. Its intricate blend of science and practical application enhances safety in numerous ways.