Key Components of White Reflective Vinyl: Exploring Retroreflective Materials

When it comes to understanding the key components of SINO white reflective vinyl and exploring retroreflective materials, it’s essential to delve into the science of how these materials work to make surfaces glow in the dark or under low light conditions. Let’s break down the explanation into three main components:

1. Retroreflective Materials

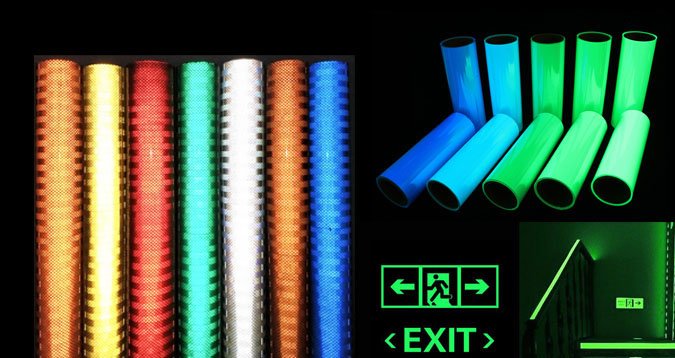

Retroreflective materials are designed to redirect light back towards its source, regardless of the angle at which the light hits the material’s surface. This property is achieved through the use of special microprisms or glass beads embedded within the material. When light strikes the surface of the retroreflective material, these microprisms or glass beads bounce the light back to its origin, such as a vehicle’s headlights or a flashlight, making the material highly visible even in dark or low-light environments.

2. Microprisms and Glass Beads

The two primary types of retroreflective materials used in white reflective vinyl are microprismatic and glass bead-based materials.

– Microprismatic Retroreflective Materials

These materials are made from tiny, corner-cube prisms that are precisely arranged on the surface of the vinyl. Each prism is designed to reflect light back to its source in a specific direction, allowing for enhanced visibility over longer distances. Microprismatic materials are often used in high-visibility applications like road signs, vehicle markings, and safety apparel.

– Glass Bead-Based Retroreflective Materials

In this type of material, thousands of small glass beads are embedded in a layer of transparent adhesive on the vinyl surface. When light hits the vinyl, it enters the transparent adhesive, and as it passes through the glass beads, it is refracted and then retroreflected back in the direction it came from. Glass bead-based retroreflective materials are commonly used in reflective tapes and decals for vehicles, helmets, and various safety applications.

3. White Reflective Vinyl

SINO White reflective vinyl is a specific type of retroreflective material that has a white-colored surface, making it ideal for applications where a bright and clean appearance is desired during the day, but nighttime visibility is still crucial. It is widely used in various industries, such as traffic safety, road signs, architectural design, sports gear, fashion, and DIY projects.

In summary, the key components of white reflective vinyl involve the use of retroreflective materials, which consist of microprisms or glass beads.

White Reflective Vinyl in Signage and Traffic Safety Applications

SINO White reflective vinyl plays a crucial role in signage and traffic safety applications, enhancing visibility during both day and night. Here are some common uses of white reflective vinyl in these contexts:

1. Road Signs

White reflective vinyl is commonly used for the text and symbols on road signs. It ensures that important traffic information is clearly visible to drivers, even in low-light conditions.

2. Traffic Signs

Whether it’s stop signs, yield signs, or speed limit signs, white reflective vinyl is often employed to improve their visibility and effectiveness, contributing to safer road conditions.

3. Directional Signage

White reflective vinyl is used for directional signs, guiding drivers, pedestrians, and cyclists to their intended destinations, especially in poorly lit areas.

4. Street Name Signs

Street name signs often incorporate white reflective vinyl to ensure they are easily readable, providing essential information for travelers.

5. Construction Signs

Temporary construction signs and barricades frequently use white reflective vinyl, making them highly visible to motorists and pedestrians even at night.

6. Parking Lot Signs

Signage in parking lots, including entrance and exit signs, as well as markers for reserved spaces, are often enhanced with white reflective vinyl.

7. Vehicle Markings

Commercial vehicles, emergency response vehicles, and fleet vehicles may have white reflective vinyl applied to their exteriors, increasing visibility and safety on the road.

8. Pedestrian Crosswalks

White reflective vinyl is used to outline pedestrian crosswalks and zebra crossings, ensuring maximum visibility for drivers to notice and yield to pedestrians.

9. School Zone Safety

Signs in school zones often feature white reflective vinyl to alert drivers to reduce speed and be cautious in the presence of children.

10. Railroad Crossings

Railroad crossing signs and barriers may incorporate white reflective vinyl to make them visible from a distance, giving drivers ample time to stop for an approaching train.

11. Bicycle Paths

Signs along bicycle paths and lanes often utilize white reflective vinyl to enhance cyclist safety, especially during darker hours.

12. Highway Markings

White reflective vinyl is used for lane markings on highways, assisting drivers in maintaining proper lane positioning, even in adverse weather conditions.

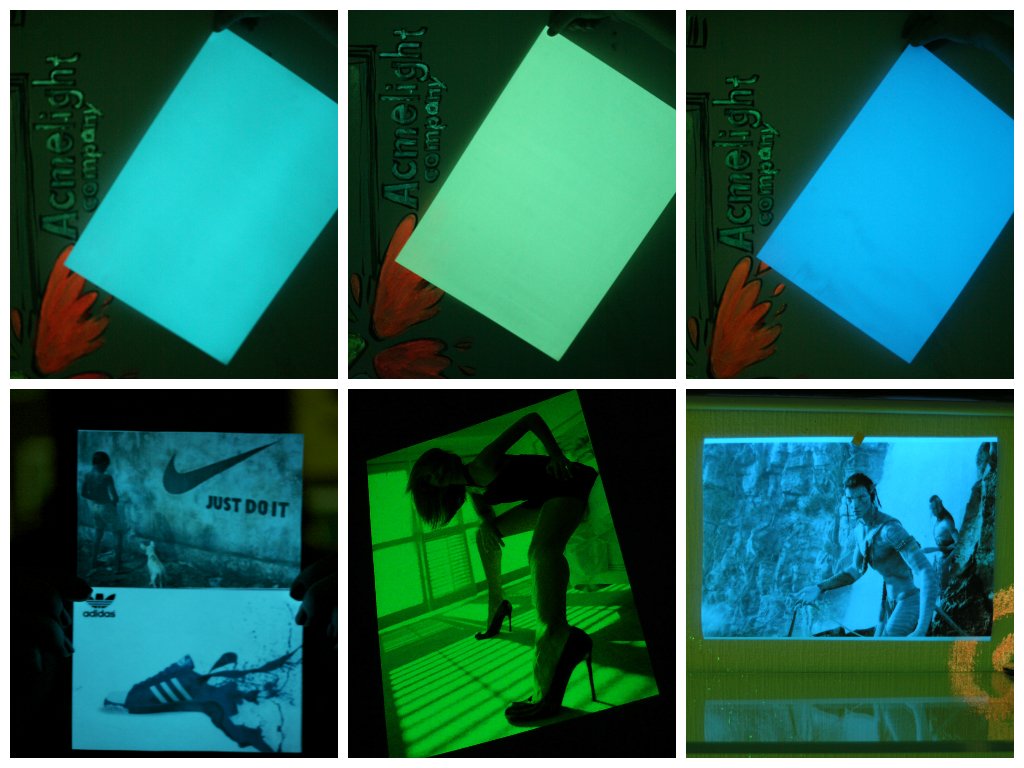

13. Emergency Exits and Safety Markings

In buildings and facilities, white reflective vinyl is employed for emergency exit signs and safety markings to guide people during evacuation scenarios.

14. Airport Runway Markings

On airport runways, white reflective vinyl is utilized for runway centerlines and other markings, aiding pilots during takeoff, landing, and taxiing.

15. Hazardous Materials Signage

Signs indicating hazardous areas or materials often incorporate white reflective vinyl for clear and easily discernible warnings.

Overall, white reflective vinyl in signage and traffic safety applications significantly improves visibility and contributes to the overall safety of road users and pedestrians, making it an essential material for various industries and situations.